- bearings

- spherical bearings

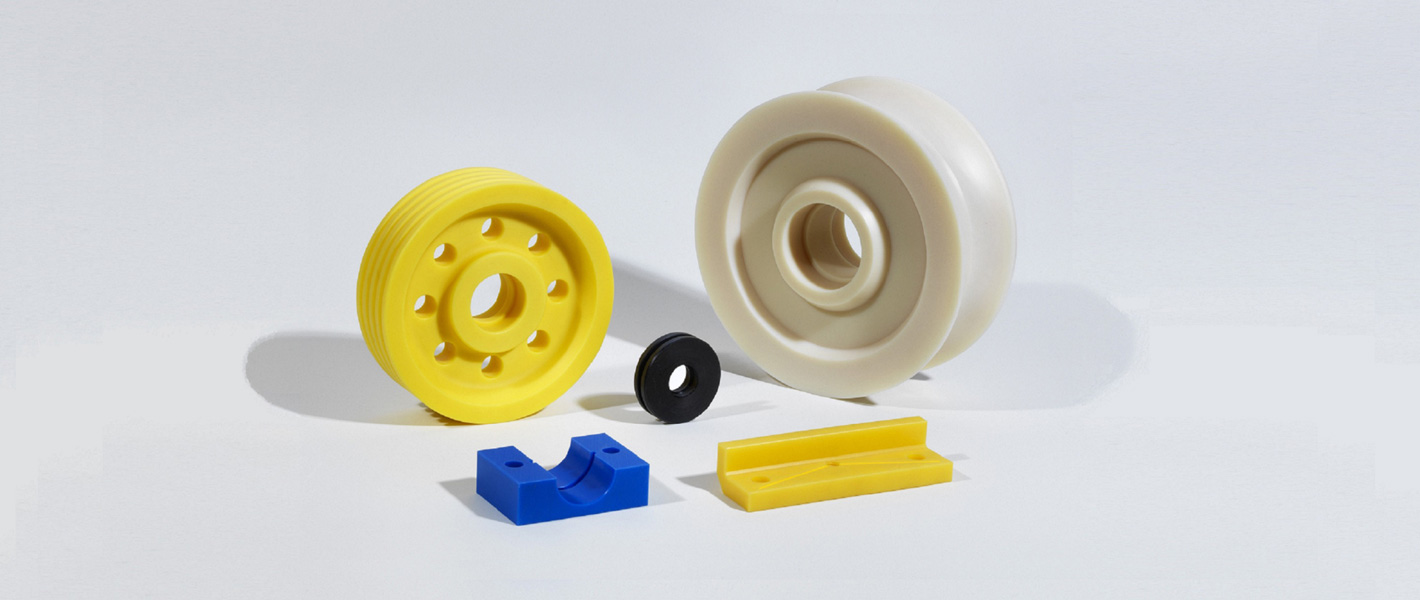

- engineering plastics

- friction material

- insulation material

There are innumerable places where moving parts can wear out due to friction. In many such places, adding a plastic buffer is highly beneficial. Plastic applications are effective in many areas, such as:

- Complex machinery

- Machinery with very large or very small parts

- Machinery subjected to high levels of compressive or tensile forces

- Machinery in very hot or very cold environments

- Machinery in wet environments

- Machinery that must be strong, as well as flexible

We successfully deal with these challenges on a daily basis. We have all the requisite inhouse knowledge and are in close contact with manufacturers to enable us to effectively deal with these challenges. We ensure that the parts meet all applicable conditions. By zeroing in on your requirements and/or problem, we always provide you with the right solution.

The plastic component’s properties

What are the conditions that the component must be able to withstand? Where is the component to be used? These are our very first questions and the answers provide the basis that enables us to find the right solution. For example, some materials must be able to withstand high temperatures, but also must be able to move. By contrast, other materials must be highly resilient or must exhibit high internal strength.

Over the past 30 years we have accumulated a great deal of knowledge about the application of plastics in moving parts and guiding devices, and for mechanical loads. And we are adding new knowledge on a daily basis. This is our profession and our passion.

Zooming in on a mechanical component

We first study the mechanical component. This can be from a drawing, or on the basis of a new or used joint. In case of a used mechanical component, we measure the degree of wear to discover where the greatest force is being exerted. We then use this data to calculate which components should be combined. Next, in close consultation with the manufacturer, we adjust the composition of the basic material to provide the best possible solution. We are the intermediary between customer and manufacturer and ensure that the customer’s needs are transformed into solutions. We then assume responsibility for the component’s production.

Assembly

Proper assembly is essential to guarantee the proper functioning of our components. We offer support during assembly and, if desired, can carry out the required assembly onsite.

Designing and adjusting components

Often a customer may have an existing design, which then becomes our starting point. Where necessary, we adjust the drawing, making it possible to produce a component with the right shape and properties. In addition, we design components from scratch.

Aside from finding the right combination of plastics, our strength and challenge lie in producing new designs and modifying existing drawings.

Comprehensive package: engineering plastics, sliding bearings and friction materials

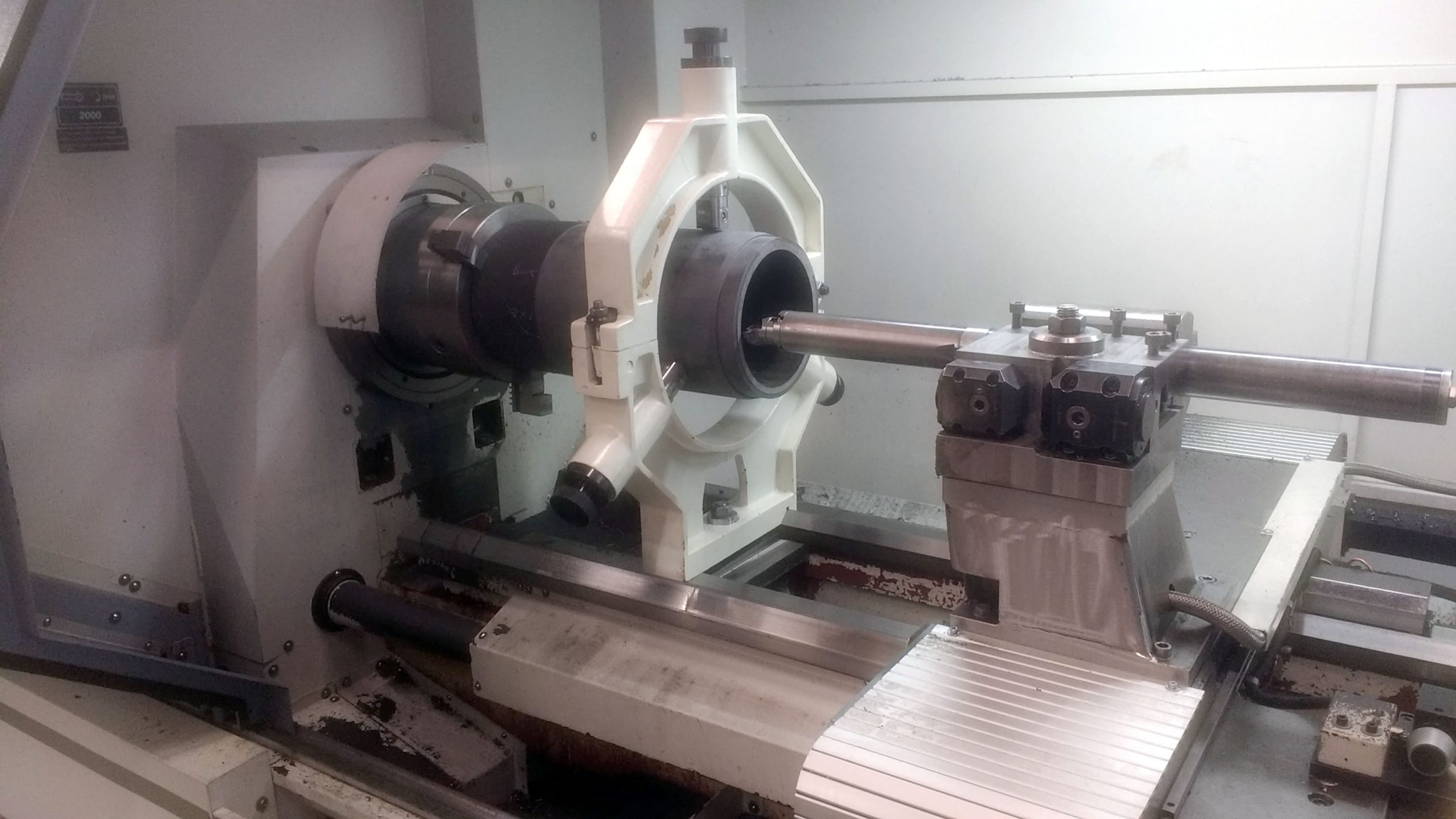

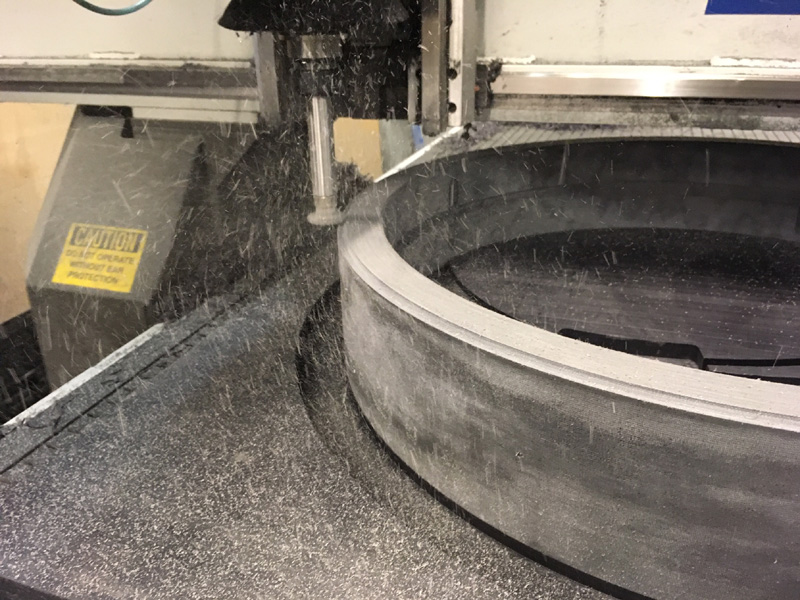

Your time is a valuable commodity. This is why we supply you with more than engineering plastics alone. When you have a need for friction materials, you generally also need sliding bearings. When it comes to plastics, the product range we can supply is virtually limitless. Ranging from semi-finished and finished products to custom-made products. We can waterjet cut, laser, mill, bore, tap or in some other way machine any material for you, which enables us to quickly produce any custom-made parts. We transform your ideas into reality.

We are a one-stop-shop for engineers. Let us know what you are looking for.