- bearings

- spherical bearings

- engineering plastics

- friction material

- insulation material

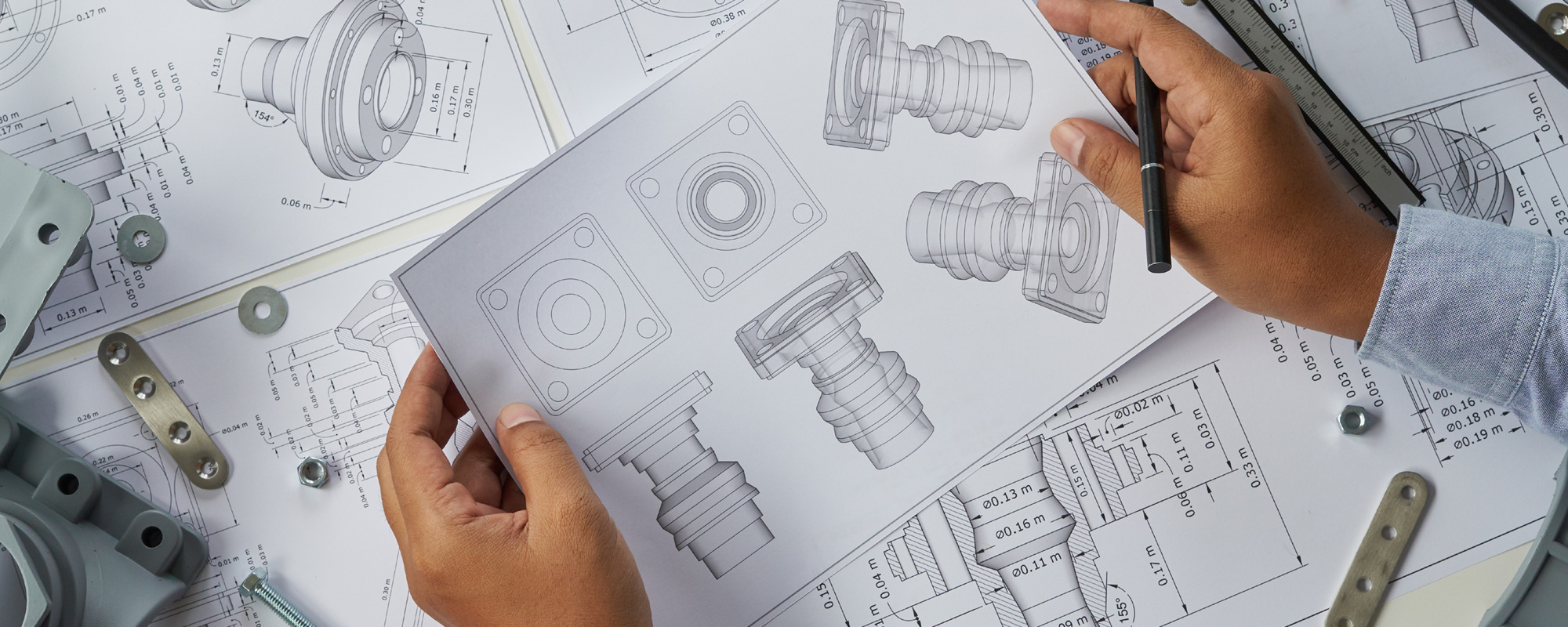

A well-thought-out design is essential for producing high quality products. After all, you require a component of a certain dimension and shape. A component that can be integrated into a specific mechanical system and that meets various specifications so that it will last longer. The starting point for our design may be a drawing, an existing joint or an idea provided by you. In consultation with you we ensure that the design meets your requirements. We then transform the design into a plastic product that meets all functional and technical specifications. During this process we look for the most economical and environmentally friendly material.

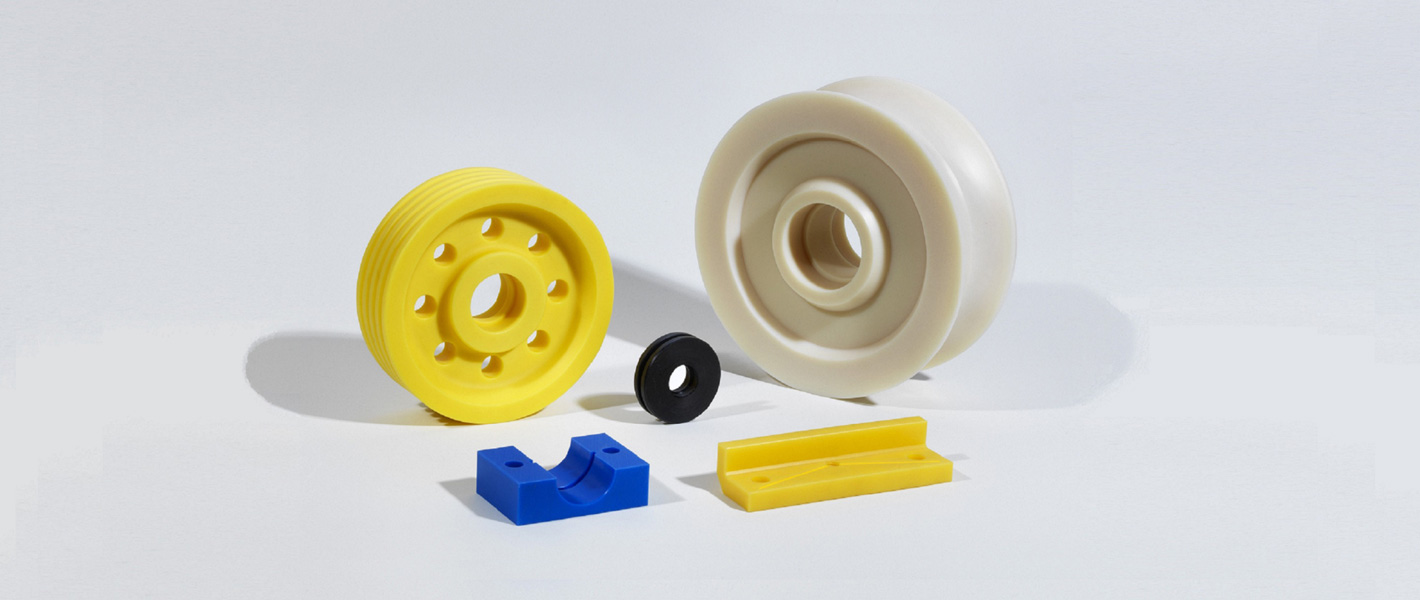

We offer three options for producing components:

- We can supply plate, bar or pipe materials that you can machine yourself.

- We can machine the material for you and supply the product in accordance with the drawing.

- We can design the product for or together with you. In this case you supply us with the drawing, the technical specifications and your requirements, and we will then supply you with the product. Alternatively, we can produce the detailed design using our 3D drawing package.

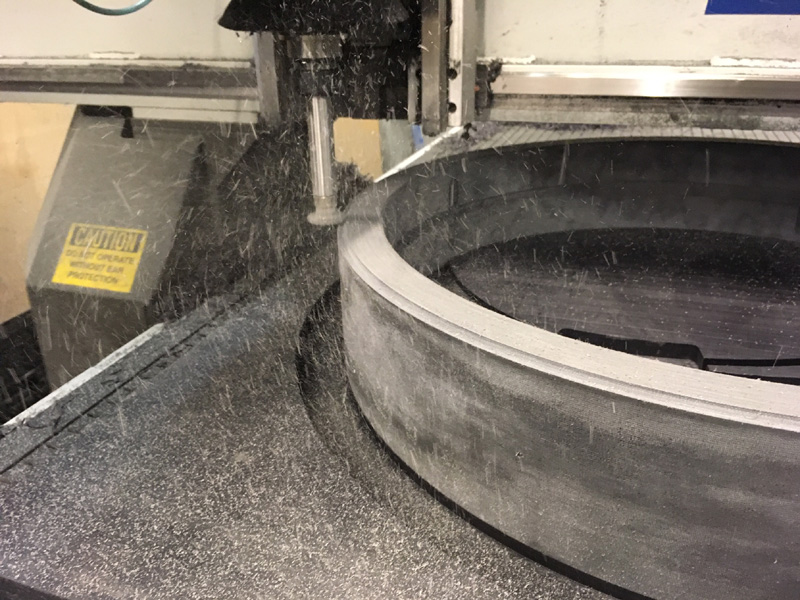

We provide you with advice to enable you to integrate the right product into your machinery. This is an application with the longest possible service life, because replacing components generally is a costly process.

Design program and consultation with manufacturers

Our engineers use advanced design programs. This way you are assured that the end result perfectly fits into your machinery. These programs are used to adjust your designs, if required, and are also used to produce new designs. Next we consult the manufacturer to ensure that the part’s composition is the best possible match for your application. By now the manufacturers know that the products we design are indeed feasible.

Production of custom-made parts

Let us know if you need certain plastic parts to be modified, so that they uniquely fit into your machinery or equipment. Often this requires some tinkering, but we always manage to find a perfect solution.

A high-quality product starts off with a thorough design

This is one of our areas of expertise and we are happy to modify an existing drawing or produce a new drawing for you. Contact us to discuss your needs.